-

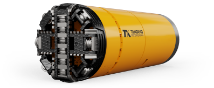

TBM

Size can be customized

Size can be customized Applicable Geology: Full Face Rock

Applicable Geology: Full Face Rock

Shield TBM

Size can be customized

Size can be customized Applicable Soil:Rock

Applicable Soil:Rock

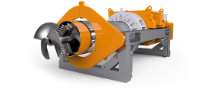

Hard Rock

Φ600mm-Φ4000mm

Φ600mm-Φ4000mm Applicable Geology:Rock

Applicable Geology:Rock

Slurry Balance

Φ450mm-Φ4000mm

Φ450mm-Φ4000mm Applicable Geology: Soft Soil

Applicable Geology: Soft Soil

Earth Balance

Φ450mm-Φ4000mm

Φ450mm-Φ4000mm Designed for different types of soil

Designed for different types of soil

Rectangular

Size can be customized

Size can be customized Designed for different types of soil

Designed for different types of soil

Auger Boring

Φ300mm-Φ600mm

Φ300mm-Φ600mm Applicable Geology: Sand, silt and clay

Applicable Geology: Sand, silt and clay

Microtunnelling Machine

Φ≤600mm

Φ≤600mm Designed for different types of soil

Designed for different types of soil

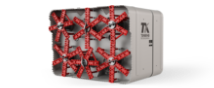

Others

Corollary equipment for pipe jacking machines

The "Qinshan No. 1" TBM Was Successfully Launched

2023-08-25

Operation Department

On August 23rd, the "Qinshan No. 1" TBM (full-face hard rock tunnel boring machine) was successfully launched for the tunnel project of the Qinshan Nuclear Power Auxiliary Steam Networking Project. This milestone marks the project's entry into the TBM construction phase.

The tunnel for this project spans approximately 1001.5 meters, traversing tuff formations primarily composed of Class III, IV, and V surrounding rocks, with rock hardness ranging from 30 to 80 MPa. To address the project's unique characteristics, Tangxing Technology assembled a team of professional technical experts to form a research and development team. They comprehensively considered actual construction conditions and devised precise solutions to a range of technical challenges, including rail transportation with small sections and steep slopes, as well as long-distance rapid excavation of small sections. Innovative enhancements were made to various systems, including the cutter head, shield, and propulsion support. Within a span of just 60 days, Tangxing Technology's R&D team completed all preliminary manufacturing preparations, encompassing mechanical design, hydraulic design, and process design. In a remarkable achievement, the "Qinshan No. 1" was developed and delivered within a mere three months, providing robust support for the smooth initiation of the TBM.

The "Qinshan No. 1" TBM boasts a 4-meter excavation diameter, weighing a total of 220 tons and measuring 72 meters in length. Tailored features such as the TBM heavy-duty cutter head, multi-section shield, three-dimensional mucking system, and variable support system were strategically incorporated to fulfill the demands of efficient and extended hard rock excavation. Noteworthy attributes include exceptional safety, remarkable flexibility, high rock-breaking performance, adaptable field transitions, and minimal environmental impact.

The project's completion holds paramount significance. It will enhance the reliability of the auxiliary steam systems at Qinshan Nuclear Power Plants 1 and 2, as well as Fangjiashan Units. Additionally, it will reduce the long-term standby energy consumption and operational costs of electric boilers, while achieving seamless connectivity for the auxiliary of Qinshan Nuclear Power Plant 2 and Fangjiashan’s steam systems.

customize your industry-specific solutions online

- EUROPETangxing_Edward

+6010-397 6995

+6010-397 6995 T1SERVICE@TANGXING.CN

T1SERVICE@TANGXING.CN - MIDDLE EAST OR ASIATangxing_Michael

+6010-293 6995

+6010-293 6995 T2SERVICE@TANGXING.CN

T2SERVICE@TANGXING.CN - AFRICATangxing_Bonnie

+6010-825 6995

+6010-825 6995 T3SERVICE@TANGXING.CN

T3SERVICE@TANGXING.CN - AMERICASTangxing_lvy

+8615305547358

+8615305547358 IVY@TANGXING.CN

IVY@TANGXING.CN - Anhui Tangxing Equipment Technology Co., Ltd (Hungary branch office)Sales representative_Leo Lee

+0036304170973

+0036304170973 WWW.TANGXINGGLOBAL.COM

WWW.TANGXINGGLOBAL.COM TANGXINGEUROPA@GMAIL.COM

TANGXINGEUROPA@GMAIL.COM

sales@tangxing.cn

086-5542796608